In mobile robotic systems, drive wheels are not merely mechanical components. From an engineering standpoint, robot drive wheels function as the final execution unit of the entire motion control chain, directly influencing payload capability, motion stability, positioning accuracy, and long-term system reliability.

1. The System-Level Role of Robot Drive Wheels

A drive wheel simultaneously performs torque transmission, motion execution, and ground interaction. Its performance must align with multiple system parameters, including:

-

Total robot weight and rated payload

-

Target speed and acceleration profiles

-

Floor conditions and friction characteristics

-

Control architecture (open-loop vs closed-loop)

This is why experienced robot manufacturers rarely select wheels in isolation. Instead, they evaluate the complete drive wheel module as part of the motion system.

2. Structural Choices and Their Impact on Robot Performance

Different robot drive wheel configurations reflect different chassis design philosophies:

-

Differential drive wheels

Well-proven and cost-efficient, suitable for logistics robots with predictable paths.

They offer high reliability but limited maneuverability in confined environments. -

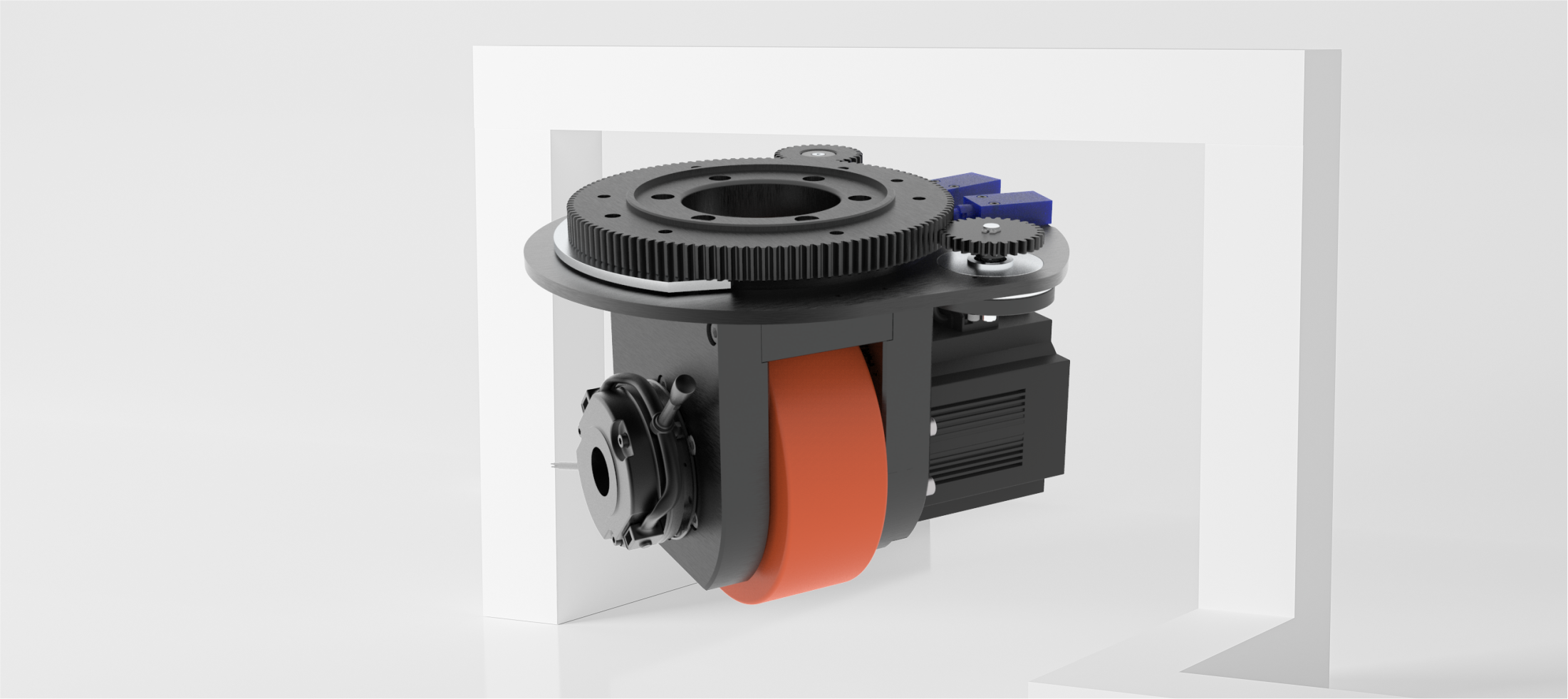

Steering drive wheels

By separating steering and driving functions, these solutions provide smoother motion control and higher positioning accuracy.

They are commonly adopted in mid- to high-end AGV and AMR platforms. -

Omnidirectional wheel systems

Designed for maximum flexibility, yet demanding in terms of control algorithms, mechanical rigidity, and wheel consistency.

Once a drive wheel architecture is defined, later adjustments in control logic or mechanical layout become constrained, making early-stage decisions critical.

3. Load and Torque Matching: A Frequently Underestimated Risk

Many drive wheel failures originate from insufficient torque margins.

In real-world applications, engineers must account for more than nominal load values:

-

Transient loads during acceleration and braking

-

Variations in floor friction

-

The influence of wheel diameter on output force

-

Thermal degradation under continuous operation

A practical engineering guideline is to maintain a 20–30% torque reserve, ensuring stable performance under non-ideal conditions.

4. Engineering Advantages of Integrated Drive Wheel Modules

Compared with traditional discrete solutions, integrated robot drive wheels offer measurable benefits:

-

Reduced installation and commissioning time

-

Standardized mechanical and electrical interfaces

-

Improved consistency across multiple robots

For manufacturers prioritizing delivery efficiency and long-term reliability, integrated drive wheel solutions are increasingly becoming the preferred choice.

5. Application-Oriented Selection Strategy

There is no universal solution for robot drive wheels. Selection should always be driven by application requirements:

-

Warehouse and logistics robots: focus on reliability and maintenance efficiency

-

Production line and docking applications: emphasize positioning accuracy and repeatability

-

Heavy-duty or continuous operation scenarios: prioritize thermal management and durability

Understanding robot drive wheels at the system level enables engineers to make informed, application-specific decisions rather than relying on generic configurations.

Drive wheels are not accessories — they define the motion quality of the robot.

Paylaşmak:

Differential Drive vs Steering Drive vs Omnidirectional Wheels: An Engineering Perspective on AGV Drive Wheel Selection

Engineering Configuration of Steering Drive Wheels for AGV Forklift Applications