In real AGV projects, customers rarely struggle with basic motion. The real challenges are related to stability, system integration, and long-term reliability.

This is where a well-designed differential drive AGV drive wheel module delivers practical value.

1. Common Issues Faced in Differential Drive AGV Projects

System integrators often encounter problems such as:

-

Vibration or drifting during straight motion

-

Inconsistent behavior between left and right drive wheels

-

Long commissioning time and poor parameter repeatability

-

Unclear service life of wheels and gearboxes under load

These issues are usually caused not by control software, but by insufficient engineering design of the drive wheel itself.

2. How a Differential Drive Wheel Module Addresses These Issues

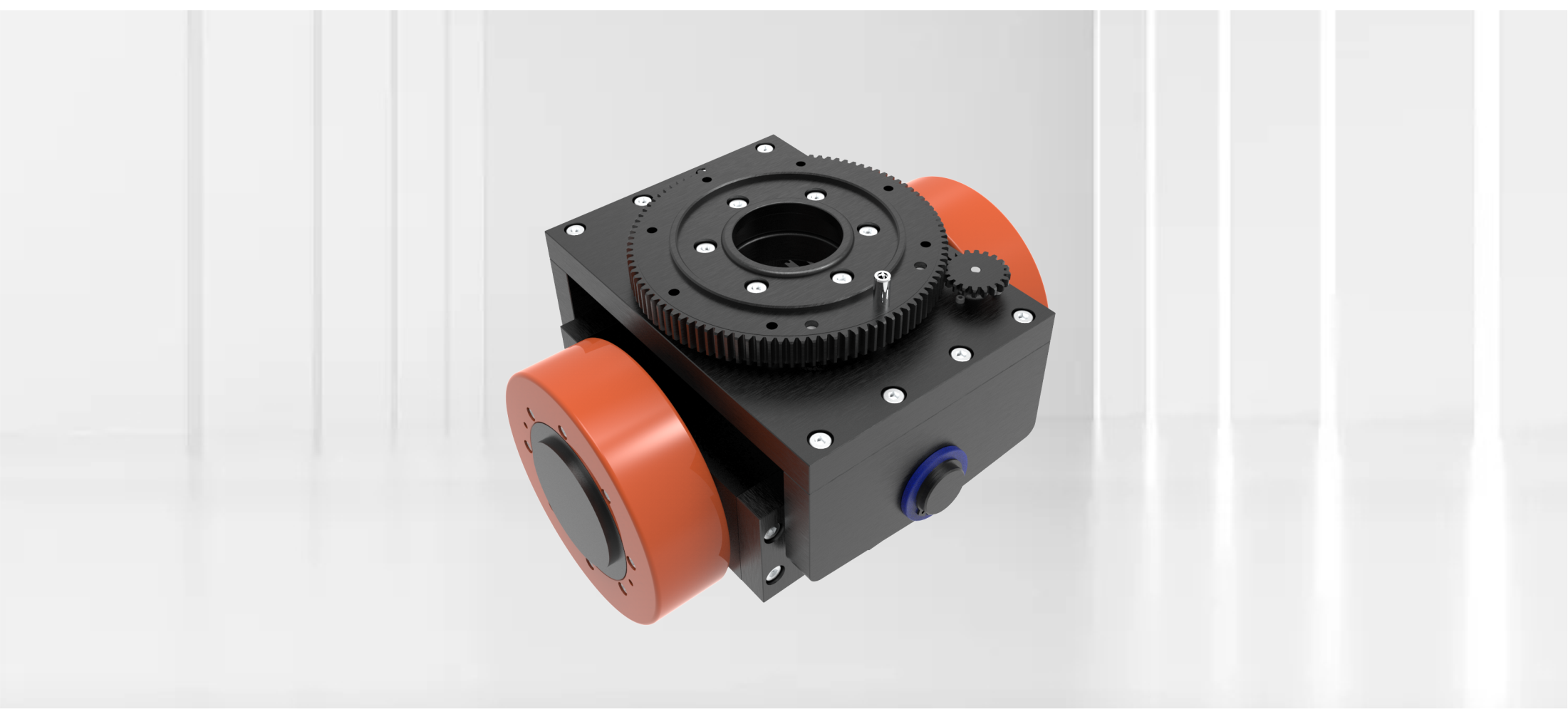

A professional differential drive module is not just a motor with a wheel. It is an engineered unit designed for AGV operating conditions:

-

Identical mechanical structure and parameters for left and right AGV drive wheels

-

Servo motors and gear ratios matched to real load and duty cycles

-

Wheel hub and bearing design optimized for long-term radial and axial loads

This ensures predictable mechanical behavior during acceleration, braking, and turning, significantly reducing tuning effort.

3. Practical Benefits During System Integration

From a project implementation perspective, differential drive wheel modules offer clear advantages:

-

Simplified control integration

Clear kinematic models compatible with mainstream AGV controllers -

Mechanical integration efficiency

Modular design that fits various chassis layouts -

Predictable maintenance

Simple structure and standardized spare parts

These factors are critical for customers planning multi-vehicle deployment.

4. What We Actually Deliver to the Customer

For differential AGV drive wheel applications, we do not deliver isolated components. We provide:

-

A matched drive solution including servo motor, gearbox, and wheel assembly

-

Defined mechanical interfaces and load limits for chassis design

-

Proven parameter recommendations to shorten commissioning time

-

Multiple configurations covering different load and speed requirements

This allows customers to focus on system-level control and navigation, without revalidating the drive foundation.

5. Conclusion: Engineering Reliability Over Complexity

In AGV projects, delivery risks are often caused by instability rather than insufficient performance.

A differential drive AGV drive wheel module is designed to reduce uncertainty, minimize rework, and support long-term operation.

Its value lies not in complexity, but in helping customers build reliable AGV systems with confidence.

Compartir:

Heavy-Duty 1.5-3 Ton AGV Lifting & Rotating Module for Smart Warehouse Automation

Differential Drive vs Steering Drive vs Omnidirectional Wheels: An Engineering Perspective on AGV Drive Wheel Selection