Understanding AGV/AMR Wheels

AGV wheels are engineered to support the vehicle's weight while facilitating smooth movement across diverse surfaces. These wheels come in various designs, with drive wheels responsible for propulsion and steering wheels enabling precise navigation.

Types of Wheels in AGV/AMR Systems

-

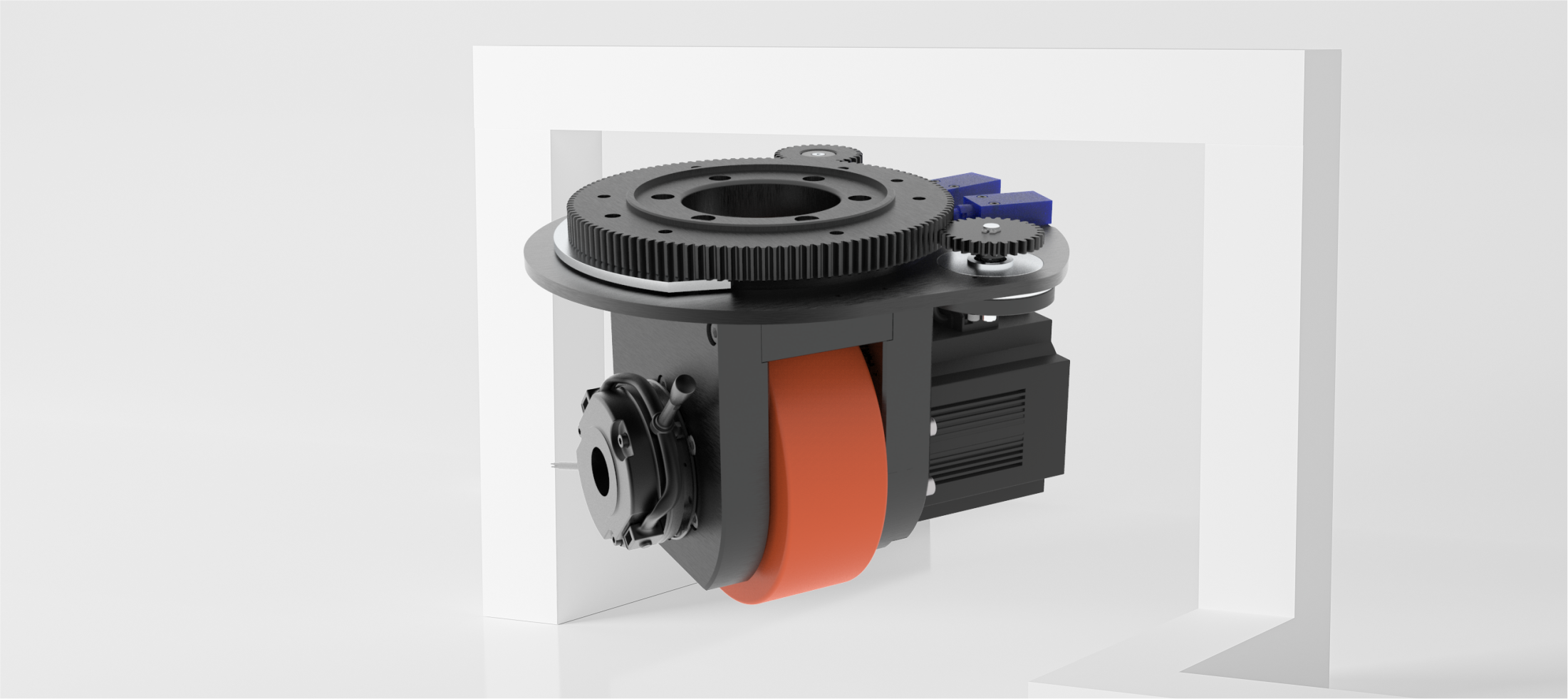

AGV/AMR Drive and Steering Wheels

- Drive Wheels: Propel the vehicle forward and backward.

- Steering Wheels: Allow for tight turns and complex navigation, enhancing agility and responsiveness.

-

Forklift Steering Wheels

- While traditional forklifts use steering wheels for maneuvering in narrow aisles, AGVs adopt similar functionalities to navigate constrained spaces.

The Role of Steering Wheels in AGV Performance

Steering wheels are crucial for precise control over the AGV's direction, offering several key benefits:

- Maneuverability: Enables navigation in tight spaces, making AGVs ideal for crowded warehouse environments.

- Stability: Well-designed steering wheels enhance the vehicle’s stability, particularly under heavy loads, reducing the risk of tipping.

-

Efficiency: Streamlined steering mechanisms minimize the effort needed to change direction, resulting in faster and more responsive operations.

Applications of AGV Steering Wheels

Steering wheels are integral to AGVs across multiple industries, including:

- Warehousing and Logistics: AGVs efficiently transport goods in distribution centers, lowering labor costs and boosting throughput.

- Manufacturing: AGVs facilitate material delivery along production lines, improving overall efficiency.

- Healthcare: In hospitals, AGVs equipped with steering wheels transport supplies and medications, enhancing workflow and patient care.

Product Applications

Several products benefit from AGV steering wheels, including:

- Automated Forklifts: Essential for heavy lifting and movement in warehouses, requiring precise steering for optimal performance.

- Delivery Robots: In urban settings or large facilities, these robots depend on effective steering for navigating complex layouts.

- Material Handling Vehicles: AMRs for transporting raw materials or finished goods in manufacturing environments utilize steering wheels for improved maneuverability.

- Mobile Cleaning Robots: These units require precise navigation to efficiently clean designated areas, highlighting the necessity of steering wheels.

Conclusion

Steering wheels are fundamental to the functionality and efficiency of AGV systems. Their design and performance significantly influence maneuverability, stability, and operational effectiveness. As the landscape of automation continues to advance, innovations in wheel technology will further enhance the capabilities of AGVs and AMRs, driving transformative changes across various industries.

Share:

Essential Role of Servo Gearboxes in Automation and Robotics

Key Considerations for AGV Wheels: Enhancing Automation Performance