Automated Guided Vehicles (AGV) play a pivotal role in modern industrial automation, enhancing efficiency and productivity. A critical aspect of AGVs is their wheels, which vary in design and function to suit specific applications. This article explores various types of AGV wheels, including differential wheels, driven wheels, and horizontal steering wheels, as well as the importance of choosing the right manufacturer and materials.

Types of AGV Wheels

1. Differential Wheels

Differential wheels are designed to allow AGVs to pivot and turn smoothly, making them ideal for navigating tight spaces. These wheels enable independent movement, which enhances maneuverability in complex environments like warehouses or manufacturing floors.

2. Driven Wheels

Driven wheels are the primary source of propulsion for AGVs. These wheels are powered by motors and are responsible for moving the vehicle forward or backward. The design of driven wheels can significantly impact the vehicle's overall performance, especially when it comes to load capacity and speed.

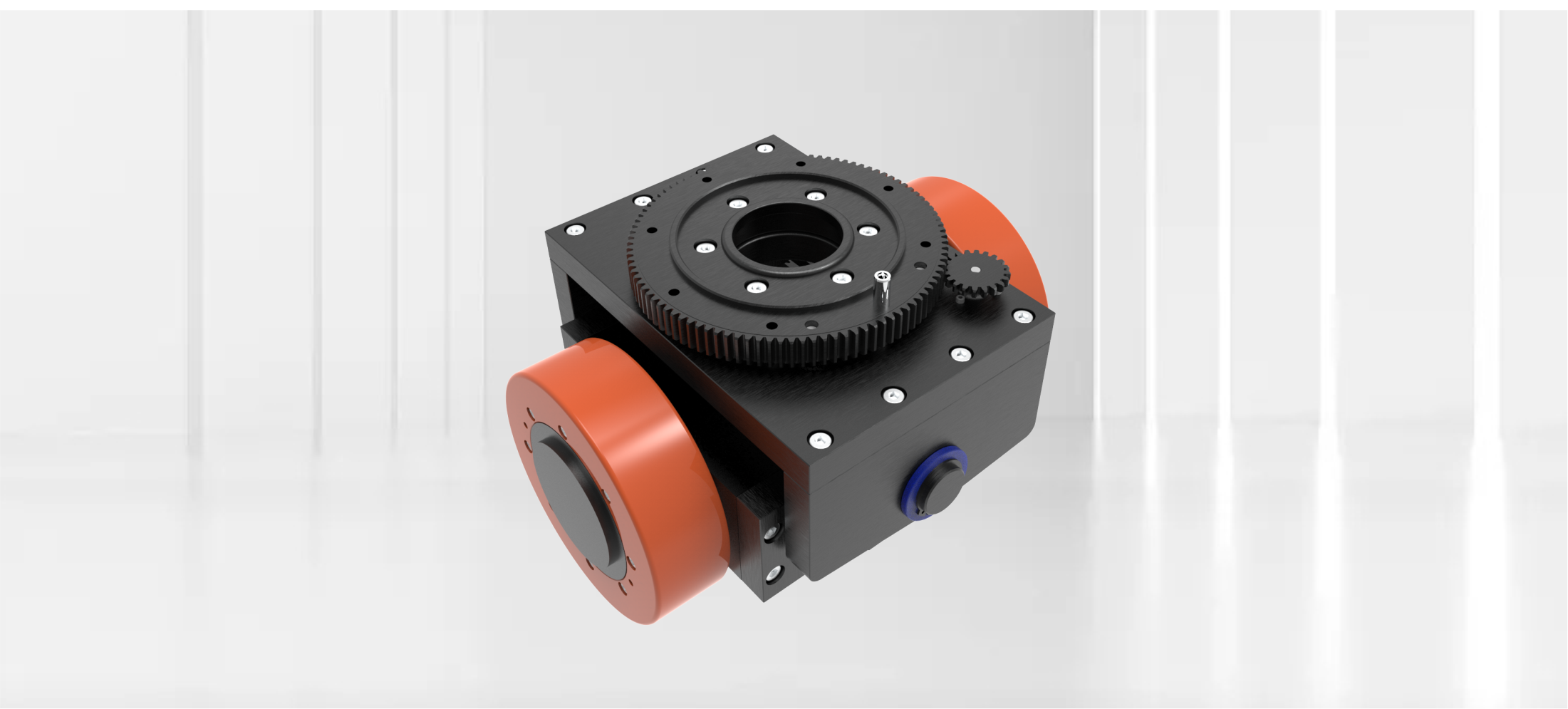

3. Horizontal Steering Wheels

Horizontal steering wheels are essential for AGVs that require precise directional control. These wheels enable the vehicle to make sharp turns and navigate tight corners, which is particularly important in environments with limited space.

Choosing the Right AGV Wheel Manufacturer

Selecting a reliable AGV wheel manufacturer is crucial for ensuring quality and durability. A reputable manufacturer will offer a range of options, including:

- Durable AGV Wheels: Designed to withstand heavy loads and frequent use, ensuring longevity and reduced maintenance costs.

- Heavy-Duty AGV Wheels: Ideal for environments that require robust performance, such as warehouses with heavy machinery or materials.

- Robust AGV Wheels: Engineered for reliability in demanding conditions, providing consistent performance over time.

Suspension and Automation

AGV wheel suspension systems can enhance the vehicle’s stability and performance. A well-designed suspension helps absorb shocks and reduces wear on wheels, improving the overall ride quality. This is especially important in automated settings where precision and stability are paramount.

Pricing and Value of AGV Wheels

AGV wheel prices can vary significantly based on material, design, and manufacturer. While it’s tempting to opt for the lowest price, investing in high-quality wheels can lead to better performance and lower long-term costs. It's essential to balance upfront expenses with the potential for durability and efficiency.

Applications of AGV Wheels

AGV wheels are used in various sectors, including:

- Manufacturing: For transporting materials and products along production lines.

- Warehousing: To move goods efficiently within distribution centers.

- Healthcare: For transporting supplies and medications within hospitals.

Conclusion

The choice of wheels is vital for the effectiveness of AGVs in automation. Understanding the types of wheels—such as differential, driven, and horizontal steering wheels—and selecting a trustworthy manufacturer can significantly impact performance and reliability. As industries continue to adopt AGVs, the demand for durable and robust wheel solutions will only increase, making informed choices essential for success in automated environments.

Share:

Steering Dynamics in AGV/AMR: The Essential Role of Wheels for Efficiency and Control

DC Servo Motor Control Systems Principles and Applications