Vertical Drive Wheel for Forklift | Heavy-Duty Steering & Driving Module

Pairs well with

1. Product Overview

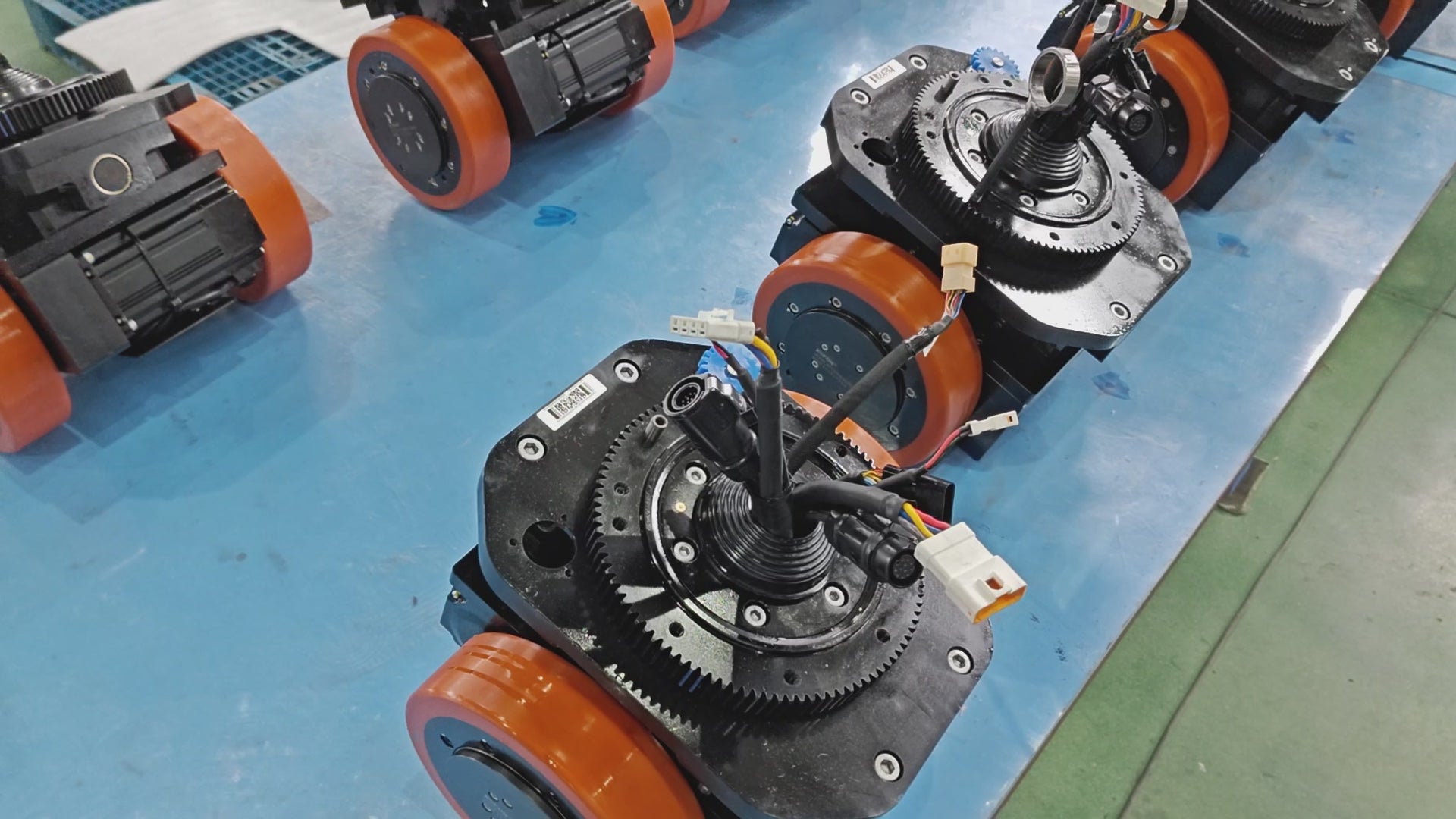

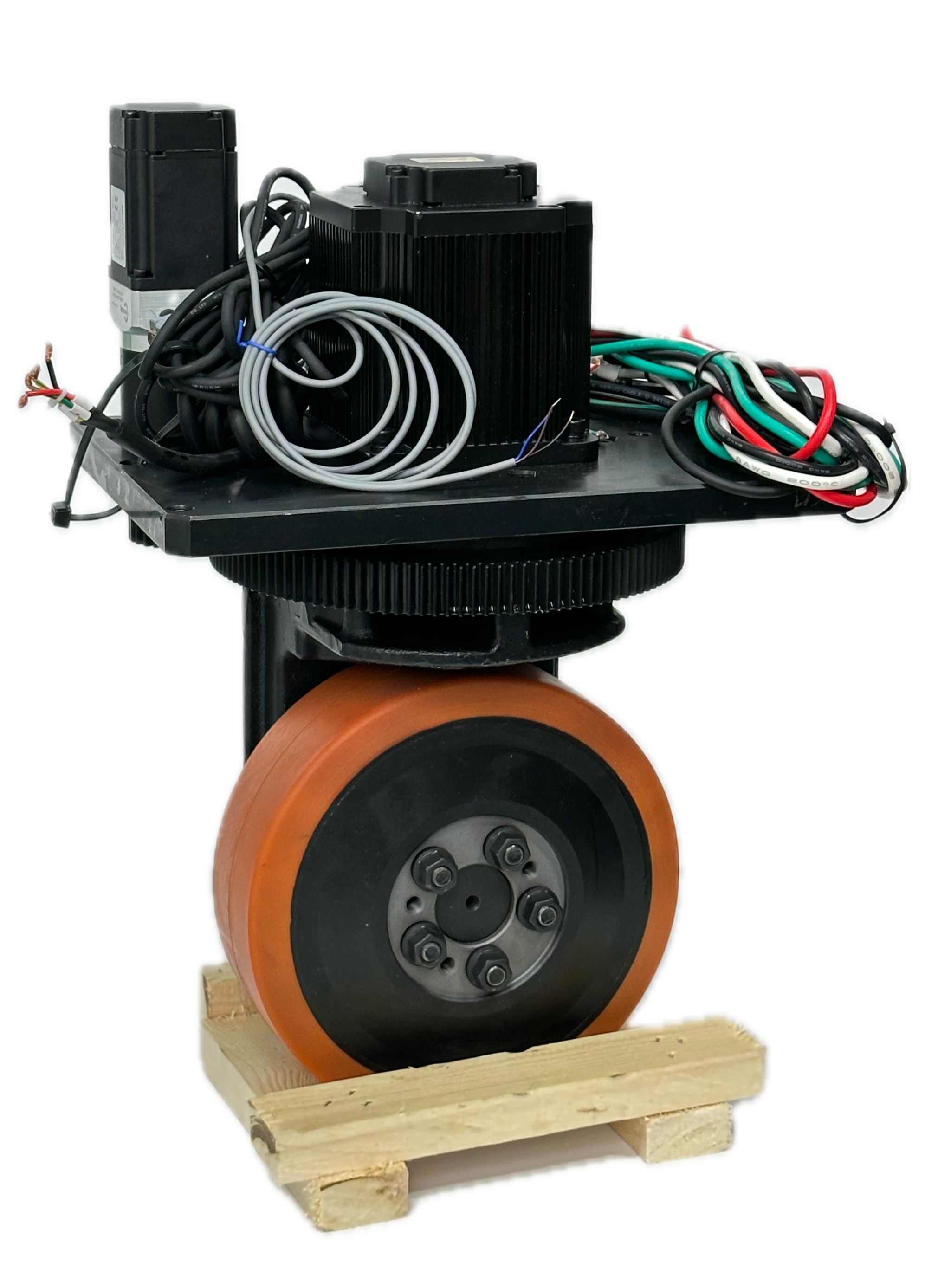

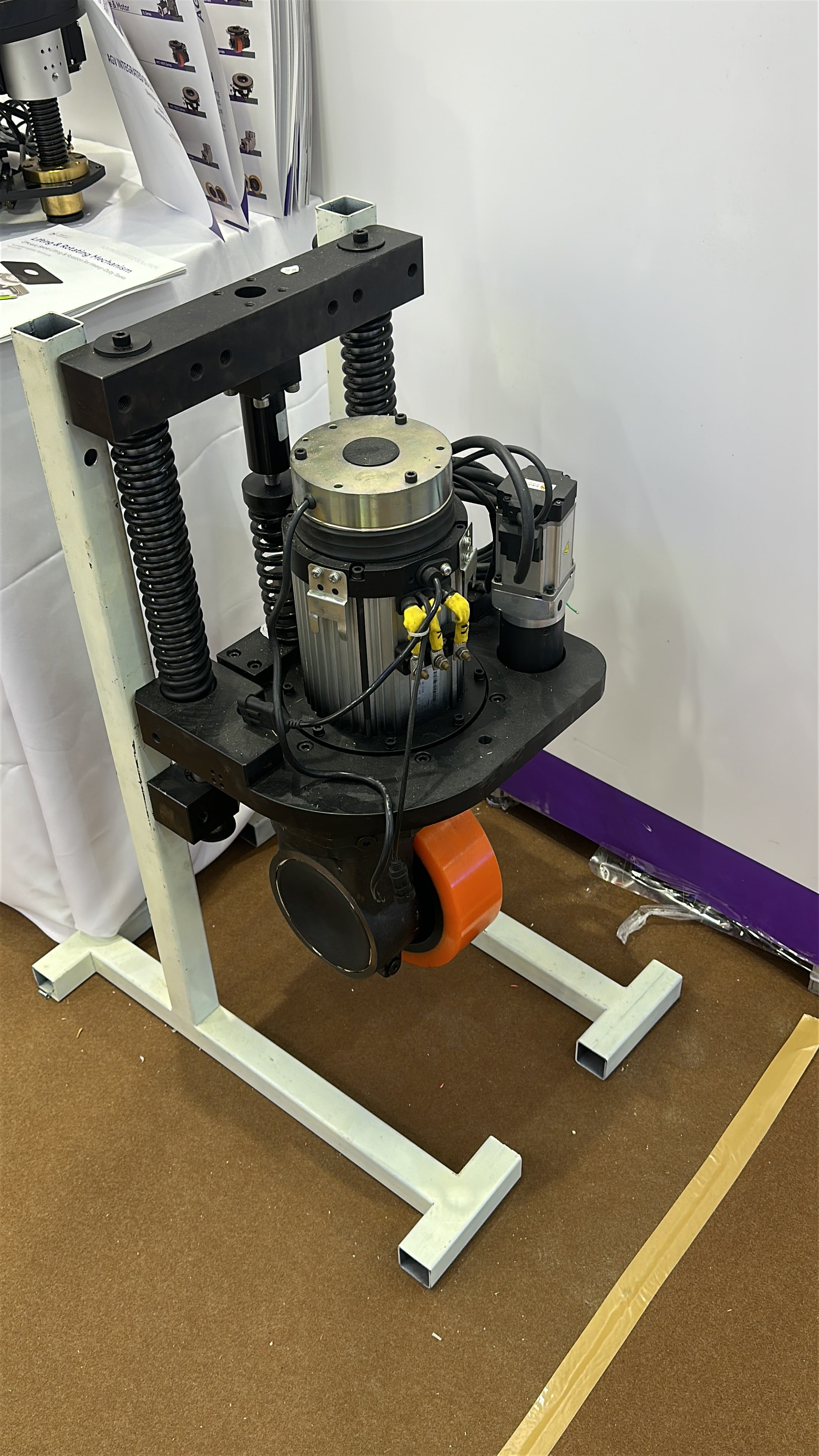

The vertical steering wheel—also known as a vertical drive wheel—is a highly integrated mobility solution designed for AGVs, AMRs, forklifts, and heavy-duty material-handling robots. By combining the steering module and the traction drive into a single compact assembly, the unit provides outstanding maneuverability in narrow aisles, high-density warehouses, and flexible manufacturing environments.

With a load capacity ranging from 500 kg to 6.5 tons, it supports both medium-duty and heavy-duty industrial logistics applications, enabling stable performance even under continuous operation.

2. Industry Challenges & System Value

Modern warehouse robots and industrial AGV platforms often encounter design limitations such as insufficient turning space, the need for higher torque in heavy-load conditions, and increasingly demanding requirements for 24/7 uptime. Traditional drive units occupy valuable chassis space and increase maintenance complexity.

The vertical drive wheel addresses these challenges by integrating traction and steering into a vertical mechanism. This design reduces chassis footprint, improves torque density, and provides more flexibility for AGV/AMR chassis layout, making it a preferred solution for intelligent warehouse robots, industrial robot chassis, and omni-directional logistics vehicles.

3. Key Advantages

• Minimal turning radius for narrow-aisle navigation

The vertical steering architecture allows the AGV to rotate smoothly in confined pathways, supporting high-density warehouse layouts and agile navigation strategies used in modern warehouse automation.

• High torque output for heavy-duty applications

The drive unit supports motor power from 400 W to 16 kW and delivers strong traction torque suitable for heavy material handling vehicles, autonomous forklifts, and high-load warehouse robots.

• Multiple wheel diameters and materials

Options include 150–470 mm wheel sizes and PU or rubber treads, providing enhanced wear resistance, quiet operation, or better obstacle-crossing capability depending on the robot’s application scenario.

• Industrial-grade steering control

The unit supports electronic limiters, incremental and absolute encoders, and optional electromagnetic brakes, enabling precise steering control, accurate positioning, and high-precision navigation commonly required in AGV steering wheel applications.

• Adaptable to diverse operating environments

Custom variants such as explosion-proof designs, low-temperature versions for cold-chain logistics, and high-IP protection versions allow deployment in harsh industrial and outdoor settings.

4. Application Scenarios

The vertical drive wheel is widely used in:

-

Warehouse AGVs and AMRs for pallet movement and shelf-to-person systems

-

Autonomous forklifts and compact material-handling vehicles

-

Heavy-duty transport platforms and industrial carts

-

Industrial robot chassis with omnidirectional drive architecture

-

Cold-storage and mixed indoor/outdoor logistics systems

Its high integration level and strong load-bearing performance make it an ideal drive module for intelligent warehouse robots and automated material handling vehicles.

5. Technical Specifications (Based on Provided Parameters)

A. Traction Drive Section

-

Rated Voltage: 12V / 24V / 48V / 80V / 96V

-

Motor Power Range: 400 W – 16 kW

-

Rated Current: 10 – 207 A

-

Rated Speed: 1,200 – 3,200 rpm

-

Rated Torque: 2.4 – 85 Nm

-

Reduction Ratio: i = 19 – 50

-

Output Torque: 30 – 1,684 Nm

-

Maximum Torque: 114 – 4,507 Nm

-

Load Capacity: 500 kg – 6,500 kg

-

Wheel Diameters: 150 / 230 / 250 / 310 / 343 / 406 / 457 / 470 mm

B. Steering Section

-

Rated Voltage: 24V / 48V

-

Motor Power: 200 – 3,000 W

-

Rated Current: 6 – 57 A

-

Rated Speed: 1,500 – 3,487 rpm

-

Rated Torque: 1.27 – 19 Nm

-

Reduction Ratio: 23 – 50

-

Output Torque: 30 – 305 Nm

C. Optional Configurations

-

PU / Rubber wheel

-

Electromagnetic brake

-

Incremental encoder / Absolute encoder

-

Limit switch & home switch

-

Shock-absorption structure

-

Explosion-proof / Low-temperature / High-IP versions

6. Why This Vertical Drive Wheel Boosts AGV/AMR Performance

By combining high output torque, precise steering control, compact mechanical architecture, and multi-environment compatibility, this vertical drive wheel strengthens the mobility performance of logistics robots, enhances navigation accuracy, and supports the rapid development of automated warehouse solutions.

Its adaptability makes it suitable for a wide range of AGV steering wheel designs, industrial robot chassis structures, and intelligent warehouse automation systems, making it a reliable choice for next-generation AGV/AMR platforms.

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

Contact Us

WhatsApp: +86 188 2652 6042

Email: sales@agvmotor.com

FAQs

Please read our FAQs page to find out more.

What about your lead time?

Depends on stock availability, if not in stock re-production will take about 1 month. Please contact us for stock availability.

What payment channels are available?

Our payment methods are T/T, Paypal, and we offer multiple country collection channels.

How about your after-sale service?

We can provide technical support via online communication. Within 24 hours technical support by email or calling service.

We provide 1 years warranty service.

Frequently asked question

Use this text to answer questions in as much detail as possible for your customers.

Frequently asked question

Use this text to answer questions in as much detail as possible for your customers.