1. Antecedentes técnicos

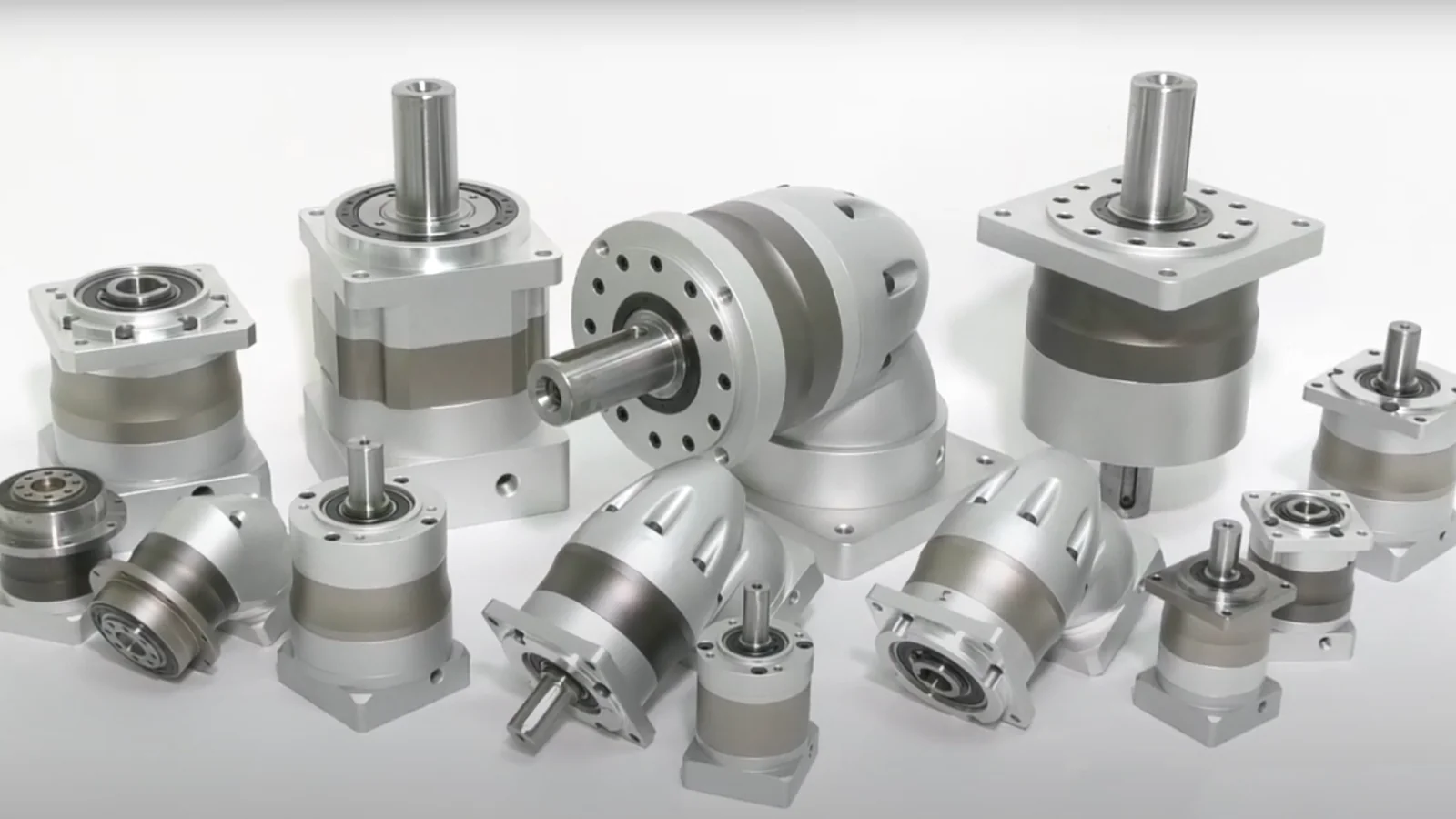

Con el continuo avance de la automatización industrial y la fabricación inteligente , la combinación de servomotores y reductores planetarios (reductores para servomotores/reductores planetarios para servomotores) se ha convertido en la solución estándar en los sistemas de control de movimiento. Los servomotores ofrecen alta precisión y una respuesta rápida , mientras que los reductores planetarios amplifican el par, reducen la velocidad y mantienen una larga vida útil y una alta eficiencia .

Referencia de mercado:

-

Se proyecta que el mercado global de servomotores y cajas de engranajes alcance los USD 9.500 millones para 2025 .

-

Los reductores planetarios para servomotores representan más del 55% en la automatización de alta gama, debido a la alta densidad de torque, bajo juego (≤3 arcmin) y alta eficiencia (≥97%) .

2. ¿Por qué combinar servomotor y caja de engranajes planetarios?

| Parámetro | Servoaccionamiento directo | Servo + caja de engranajes planetarios | Mejora |

|---|---|---|---|

| Par de salida | 1,3 Nm (400 W) | 26 Nm (relación 1:20) | ~20x |

| Precisión de posicionamiento | ±0,05 mm | ±0,03 mm | +40% |

| Velocidad máxima | 3000 rpm | 150 rpm | Adecuado para baja velocidad y alto par. |

| Vida | 10.000 horas | 20.000 horas | 2x |

| Reacción | 5 minutos de arco | ≤3 minutos de arco | Mejora de la precisión |

El uso de una caja de engranajes planetarios para servomotor permite una salida de alto torque y baja velocidad, esencial para AGV, robots, equipos médicos y sistemas logísticos inteligentes.

3. Ventajas técnicas de los reductores planetarios

-

Alta densidad de torque : tamaño compacto, gran salida de torque, relación de una sola etapa 1:3~1:10.

-

Alta eficiencia de transmisión : etapa única ≥97%, dos etapas ≥94%.

-

Juego bajo : serie de precisión ≤3 minutos de arco, adecuada para un control de movimiento preciso.

-

Larga vida útil : ≥20.000 horas.

-

Amplia compatibilidad : admite servomotores de 50 W a 15 kW.

4. Aplicaciones industriales

| Industria | Solicitud | Palabras clave y métricas técnicas |

|---|---|---|

| Automatización industrial | Máquinas CNC, embalaje | Reductores planetarios para automatización industrial , precisión ±0,02 mm |

| Sistemas de seguridad | Cámaras PTZ | Sistemas de seguridad para reductores planetarios , precisión de rotación <0,1° |

| Textiles | Hilado, tejido | Reductores planetarios textiles , salida de par a alta velocidad |

| automatización de oficinas | Impresoras, fotocopiadoras | Reductores planetarios para automatización de oficinas , rotación estable |

| Equipo médico | TC, robots quirúrgicos | Reductores planetarios médicos , bajo nivel de ruido ≤60dB, funcionamiento continuo |

| Energía solar | Seguimiento fotovoltaico | Reductores planetarios de energía solar , seguimiento de 0,1°, ganancia de eficiencia del 10 al 15 % |

| Iluminación de escenario | Control de iluminación, rotación | Reductores planetarios para dispositivos de iluminación escénica , suaves y precisos. |

| Robots | Robots colaborativos de servicio | Robots reductores planetarios , juego de articulación <5 arcmin |

| Logística inteligente | Ruedas motrices para AGV/AMR | Reductores planetarios de logística inteligente , velocidad 0,8–1,2 m/s |

| Maquinaria especial | Equipos de automatización personalizados | Reductores planetarios maquinarias y equipos especiales , alto torque y precisión |

5. Tendencias y perspectivas del mercado

-

Crecimiento : Se espera que el mercado mundial de cajas de engranajes planetarios tenga una CAGR del 7 al 9 % durante los próximos 5 años.

-

Logística inteligente : creciente demanda de reductores planetarios AGV/AMR .

-

Robótica médica : Los robots quirúrgicos requieren reductores de alta precisión y sin juego.

-

Energía renovable : los sistemas de seguimiento fotovoltaico y eólico adoptan cada vez más reductores planetarios.

Conclusión: La solución de servomotor + caja de engranajes planetarios sigue siendo central en la automatización industrial y continuará expandiéndose en robots, dispositivos médicos, logística inteligente y sistemas de energía renovable.

Compartir:

Selección de ruedas para AGV: guía técnica completa desde el material hasta los parámetros

Guía de cálculo de potencia del motor: Por qué P = F × V es importante en el diseño mecánico